GCL TECH Brought Five Leading Materials to CIIE

On November 5, the Fifth China International Import Expo (CIIE) kicked off at the Shanghai International Exhibition Center. It is reported that this year's CIIE Enterprise Exhibition attracted 66 countries and 3 international organizations, as well as 284 Fortune 500 enterprises and industry leaders with the scale and quantity surpassing the previous one.

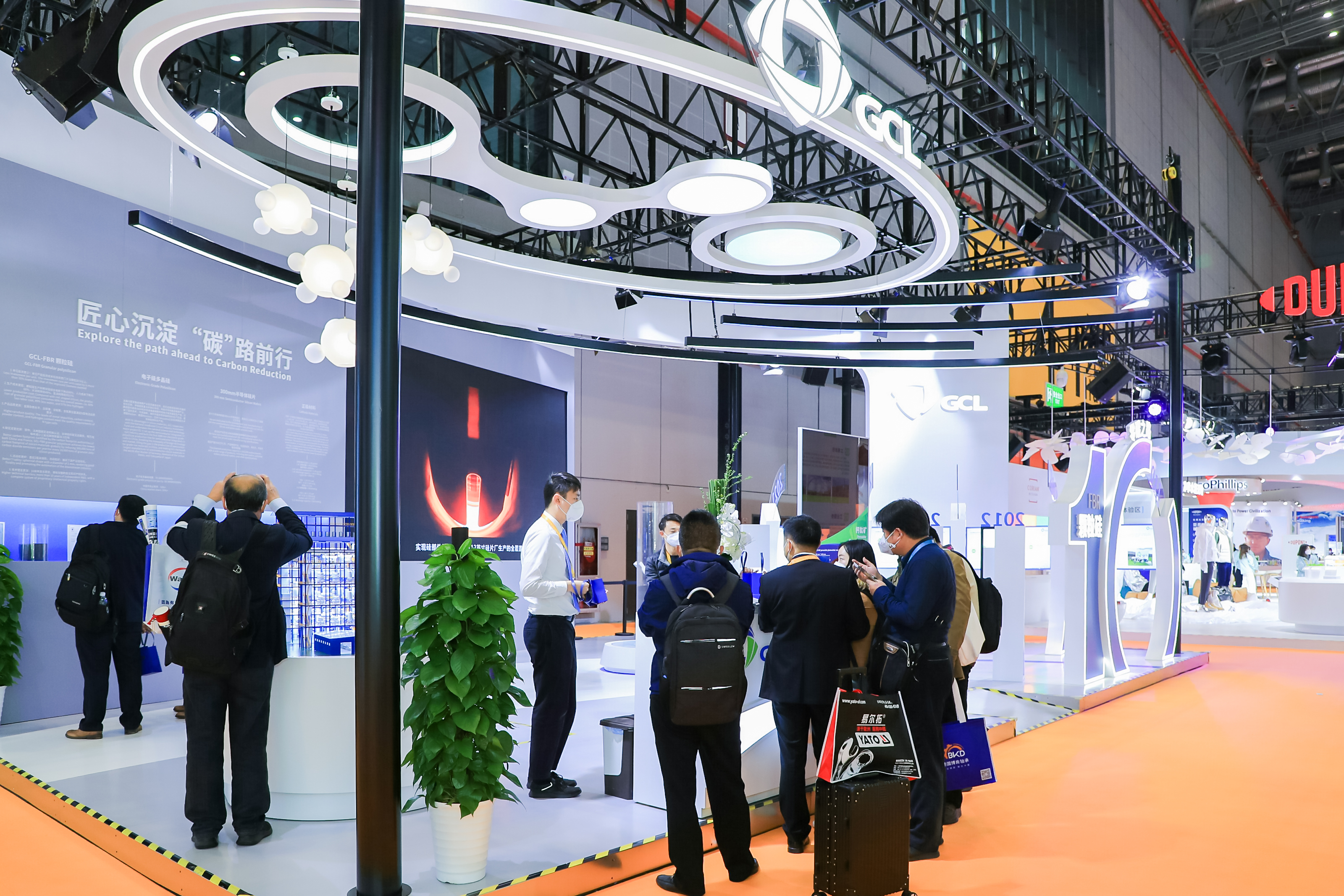

Among the global enterprises that participated, GCL TECH was the only R&D and manufacturing enterprise of new energy and high-tech materials invited, bringing its five leading materials with futuristic technologies that were particularly eye-catching: FBR granular silicon, large-scale perovskite, electronic-grade polysilicon, large semiconductor silicon wafer, and cathode material.

As the world's first national-level exhibition with the theme of import, CIIE has become a window for China to build a new development pattern and a platform to promote high-level openness for globally shared international public products, attracting more and more outstanding enterprises to show their core technology and innovation capabilities. GCL TECH is a global innovative enterprise led by leading eco-friendly, low-carbon, and zero-carbon technologies. Its appearance at CIIE reflects that the company's innovation ability, R&D achievements, and commercial applications have been fully recognized in both the domestic and overseas markets.

"We were invited to CIIE for the first time to demonstrate the most cutting-edge core technology of GCL TECH and to prove that high-tech products such as granular silicon and perovskite are gaining favor in the global market with large-scale mass production," said the relevant person in charge of GCL TECH. "We hope to integrate into the global photovoltaic industry chain and supply chain system with a more active attitude to help China's photovoltaic industry embrace the global energy revolution with core competitiveness that is more eco-friendly, less carbon-intensive, and more efficient and a high-quality brand image."

At the scene, the FBR granular silicon in the cylindrical glass jar glittered with a gray-black luster in the center of the booth, attracting guests worldwide. The sand table on the other side of the booth demonstrated the modular production process of FBR granular silicon. After learning about the technical advantages, carbon footprint performance, application results, and market scale of FBR granular silicon, many overseas guests were full of praise.

Since the launch of the FBR project in 2011, GCL TECH's experiment with this futuristic technology has achieved mass production for the first time after ten years of hard work. Currently, GCL TECH has put it into production and plans to build a total production capacity of 700,000 tons, making it the polysilicon company with the world's largest granular silicon production capacity.

As another star product of GCL TECH, the perovskite module also received high attention in CIIE. 2 meters long and 1 meter wide, with the conversion efficiency of up to 20% and the tandem conversion efficiency of over 40%, the efficient perovskite module exhibited is the largest in the world and will be mass-produced soon.

The little-known GCL US R&D Center made its debut at this CIIE. Established in 2009 in Richland, WA, GCL's US R&D Center is committed to developing the most advanced solar technology. Covering various fields such as polysilicon materials, continuous-grain silicon, cells, modules, and lithium battery anode materials, it further improves the company's production efficiency and independent R&D capability.

For more than 10 years, the US R&D Center has worked closely with the Chinese mainland team to jointly develop the disruptive core product FBR granular silicon, which fills the gap in the global production capacity of 100,000-ton granular silicon. In 2021, it obtained the carbon footprint certification in both China and France, breaking the world's record for the lowest carbon footprint of polysilicon and becoming the new benchmark of global pan-semiconductor materials in terms of carbon footprint.

"Remarkable! The advantage of carbon footprint is becoming a key index of industrial products' import and export trade. GCL's granular silicon is of great significance to carbon control and emission reduction in the whole photovoltaic industry, with the resulting carbon footprint advantage at the component end benefiting more and more enterprises," said a European exhibitor.

In addition to FBR granular silicon, GCL TECH's products with futuristic technologies such as large-scale perovskite, electronic-grade polysilicon, 300-mm semiconductor silicon wafer, and cathode materials have also become the focus of exhibitors at home and abroad. At present, GCL TECH's first 2m × 1m 100MW perovskite photovoltaic module production line in the world is about to go through mass production. Besides, GCL's electronic-grade polysilicon has been sold overseas due to its high purity and quality.

Driven by innovation, GCL TECH adheres to the principle of investing in technology at any cost. In the future, the company will introduce more and more futuristic technologies into the global energy industry chain, supply chain, and value chain.